ZB-E pressurized melt pump

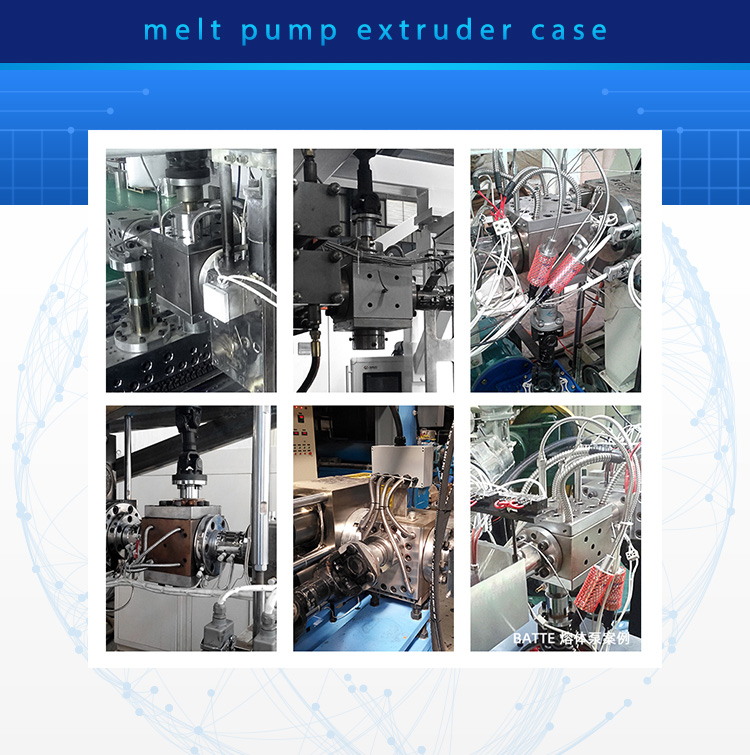

ZB-E pressurized melt pump applications:

ZB-E series circular melt pump for extrusion lines is mainly used for extruder or pressurization, stabilizing flow and transportation of medium or high viscosity polymer. This series of melt pumps for extrusion primarily adopts electrical heating, and applies to PS, PET, PVC, PC, PA, PMMA, HDPE, LDPE, LLDPE, PP, etc.

Technical Parameter of ZB-E melt pumps for extrusion:

◆ Material for Melt Pump Body: High Temperature Tool Steel

◆ Material for Gear: High Temperature Tool Steel or Nitrided Steel

◆ Material for Sliding Bearing: High Temperature Tool Steel

◆ Shaft Sealing: Spiral Sealing or Packing Sealing

◆ Heating System: Electrical Heating

◆ Model/Volume Range: 0.5CC - 2500CC, 0.5cm3/rev - 2500cm3/rev

Batte melt pump chinaplas:

Operating Parameter of ZB-E pressurized melt pump for polymer:

◆ Theory: Positive Displacement Gear Pumps

◆ Structure: Gear Pump

◆ Power: Electric or Oil

◆ Fuel: No Need

◆ Pressure: High Pressure

◆ Volume Range: 0.5CC - 3200CC

◆ Viscosity: ≤40000 Pa.s

◆ Working Temperature: ≤400°C (750°F)

◆ Cleaning Temperature: ≤450°C (850°F)

◆ Inlet Pressure: ≤12MPa

◆ Outlet Pressure: 40MPa(6000psi)

◆ Differential Pressure: ≤25Mpa

|

Type

|

CC/Rev

|

Capacity (L/H)

|

Heating power (kw)

|

Dirven system (km)

|

|

ZB-0.2

|

0.2

|

0.1-0.6

|

0.5

|

0.37

|

|

ZB-1

|

1

|

0.5-3

|

1

|

0.5

|

|

ZB-2

|

2

|

1-6

|

1

|

0.75

|

|

ZB-5

|

5

|

2.5-15

|

1

|

1.1

|

|

ZB-10

|

10

|

5-30

|

1

|

1.5

|

|

ZB-20

|

20

|

10-60

|

2

|

2.2

|

|

ZB-31.5

|

31.5

|

15-90

|

2

|

3

|

|

ZB-50

|

50

|

25-150

|

3

|

4

|

|

ZB-100

|

100

|

50-300

|

4

|

5.5

|

|

ZB-150

|

150

|

75-450

|

5

|

7.5

|

|

ZB-200

|

200

|

100-600

|

6

|

11

|

|

ZB-250

|

250

|

125-750

|

8

|

15

|

|

ZB-315

|

315

|

150-900

|

8

|

18.5

|

|

ZB-500

|

500

|

250-1500

|

12

|

22

|

|

ZB-800

|

800

|

400-2400

|

15

|

30

|

|

ZB-1200

|

1200

|

600-3600

|

20

|

37

|

|

ZB-2500

|

2500

|

1300-7500

|

24

|

45

|

Features of extruder pressurized melt pump:

◆ The steady export pressure--plastic melt pumps for extrusion can reduce the extruder output instability and pressure fluctuation caused by the extrusion machine parameters.

◆ Improve the product quality--pressurized extruder melt pump can minimize the dimensional tolerance of the extruded product and reduce the waste and scrape rate. Common extruder can also produce high precision products.

◆ Improve the output--melt pump lower the pressure requirements for the screw, change the voltage buildup way, from “screw to die-head” to “melt pump to die-head”. With the characteristic of high speed extrusion and high efficiency, the production line can adjust the extruder back pressure, reduce the staying time of melt within the screw tubes. And it also can make the plasticizing process stable, reduce the melting temperature, and improve the output and quality.

◆ Lower energy consumption unit--some data also suggests that combine the co-rotating twin-screw extruder and plastic melt pumps into mixing extruding production line, its mixing quality and output can be large increased than separate twin-screw granulator. The energy consumption can reduce about 25% generally.

◆ Prolong service life--extruder pressurized melt pump can reduce the extruder screw cylinder pressure if equipped with the melt pump, it also reduces wear between screw and screw tubes to a minimum and reduce the load of thrust bearing in gear case, accordingly prolong the production line service life. And the overflow of material in production process caused by extruder venting can be readily solved.

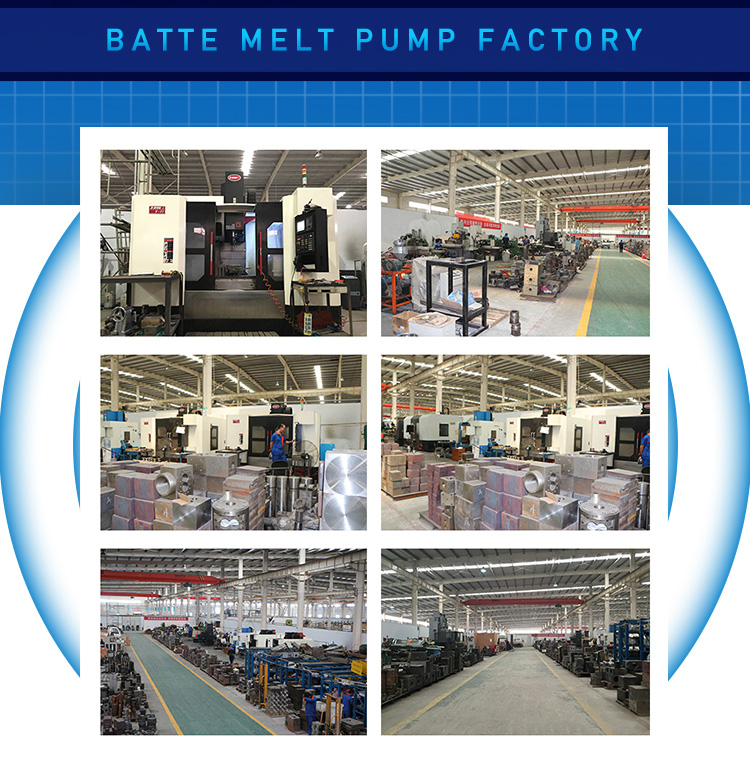

batte machinery zhengzhou CO., LTD:

Batte Melt Pump Zhengzhou Co., Ltd. is one of the manufacturers of melt pumps, gear pumps, metering pump and loss-in-weight feeders, volumetric feeders,screen changer in China. Batte has many experienced and outstanding plastic machinery talents, so it can continuously develop the new products by self-innovation or by introduction and absorbing new technology, meanwhile Batte also improves constantly the design of products and production technology service.Our pumps are widely used in plastic, resin, plate, sheet and rubber extrusion. For example, plastic extrusion machinery for PA, PP, PS, PE, PET, PC, ABS and so on is all using melt pumps to eliminate extruders' surge and screws' beat.

pre:ZB-K polymer discharge gear pump

next:ZB-H high temperature & high pressure extruder pump