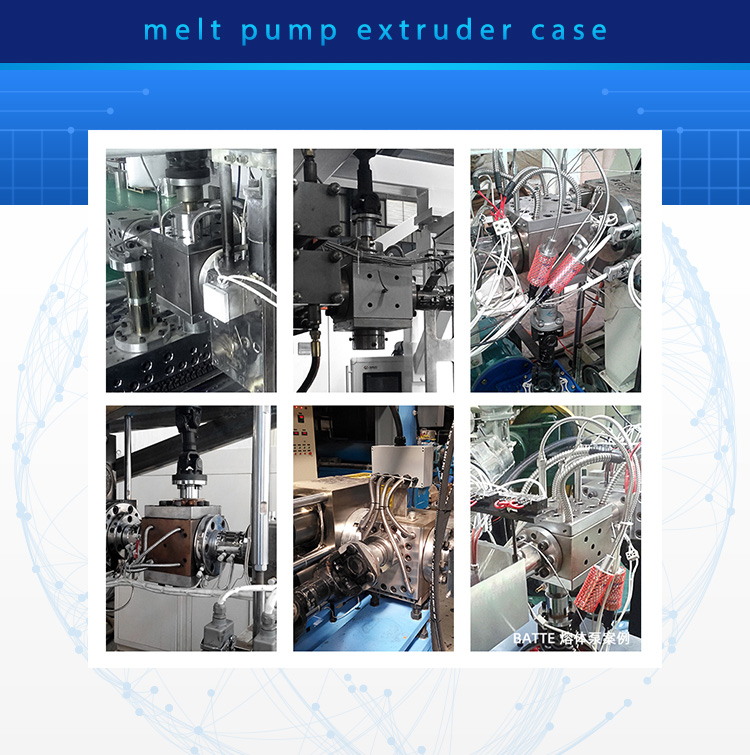

ZB-F melt pump for reactor

ZB-F melt pump for reactor applications:

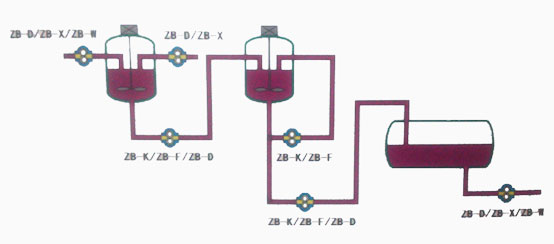

ZB-F series gear pump for reaction kettle is mainly used for transporting medium or high viscosity medium out of the vacuum reaction kettle. On basis of large suction inlet flange design, the high viscosity medium is able to absorb inside under vacuum conditions. This series melt pump for reactor is primarily applicable for ABS, PS, PC, PET, SAN, PP, PE Biopolymers, etc.

These chemical metering melt pump for reactor is mainly used in chemical engineering, chemical fiber, spinning, oil, food industry, biology, medical, and so on. Such as dacron, acrylic fibers, high strength polyethylene, resin, medical, binding agent, polyol, oil and other industries. With the increasing development of mechanical industries, this melt pump is increasingly accepted and applied by domestic.

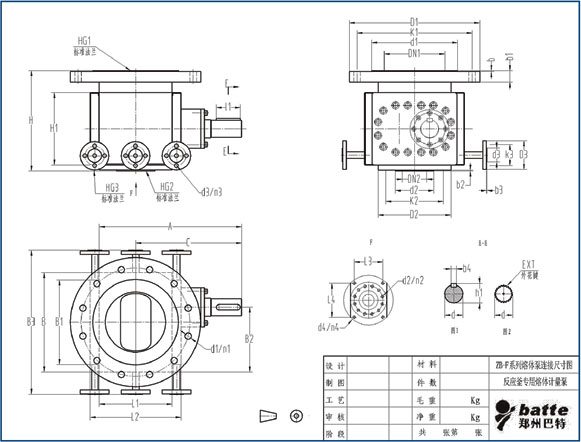

Technical Parameter of reaction kettle gear pump:

◆Material for Melt Pump Body: stainless steel, carbon steel, hatelloy, monel metal

◆Material for Gear: M2 Steel (Optional), tool steel, nitrided steel, special materials or coating

◆Gear Tooth Type: straight gear, helical gear, herringbone gear

◆Material for Sliding Bearing: Tool steel, titanium tantalum alloy, silver nickel, special materials or abrasion-resistant coating

◆Shaft Sealing: Mechanical sealing, packing and spiral packing, combined

◆Heating System: Conduction oil heating or biphenyl gas heating

◆Model/Flow Range: 0.5CC - 12000CC, 0.5cm3/rev - 12000cm3/rev

Batte melt pump chinaplas:

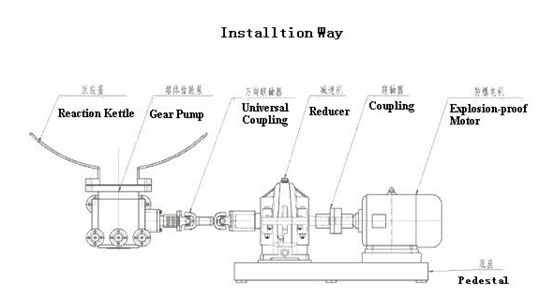

Operating Parameter of Melt pump for reactor:

◆ Theory: Positive Displacement Gear Pump

◆ Structure: Gear Pumps

◆ Usage: Plastic, Rubber Pump and Fiber

◆ Power: Electric or Oil

◆ Fuel: No Need

◆ Pressure: High Pressure

◆ Volume Range: 0.5CC - 12000CC

◆ Viscosity: ≤40000 Pa.s

◆ Working Temperature: ≤400°C(750°F)

◆Cleaning Temperature: ≤450°C(850°F)

◆ Inlet Pressure: Vacuum--1.5MPa

◆Outlet Pressure: vacuum – 1.5MPa

◆Differential Pressure: ≤25MPa

◆ Outlet Pressure: 40Mpa

|

Pump Model

|

Pump Volume (CC)

|

Driven Power (kw)

|

Heating Power (kw)

|

Working Temperature

|

Working Pressure

|

|

ZB-0.6

|

0.6

|

0.37

|

0.5

|

≤400℃(750°F)

|

Outlet Pressure: ≤ 40Mpa(6,000psi)

Outlet Differential Pressure: ≤ 275bar

|

|

ZB-1.2

|

1.2

|

0.75

|

0.5

|

||

|

ZB-2

|

2

|

0.75

|

1

|

||

|

ZB-5

|

5

|

1.1

|

2

|

||

|

ZB-10

|

10

|

1.5

|

2

|

||

|

ZB-20

|

20

|

2.2

|

2

|

||

|

ZB-31.5

|

32

|

3

|

2

|

||

|

ZB-50

|

50

|

4

|

3

|

||

|

ZB-100

|

100

|

5.5

|

4

|

||

|

ZB-150

|

150

|

7.5

|

5

|

||

|

ZB-90/90

|

200

|

11

|

6

|

||

|

ZB-100/100

|

250

|

15

|

8

|

||

|

ZB-100/100

|

315

|

18.5

|

8

|

||

|

ZB-115/115

|

500

|

22

|

12

|

||

|

ZB-130/130

|

800

|

30

|

15

|

||

|

ZB-160/160

|

1200

|

37

|

20

|

||

|

ZB-180/160

|

2500

|

45

|

24

|

||

|

ZB-180/180

|

3200

|

55

|

24

|

||

|

ZB-224/224

|

6000

|

75

|

30

|

Features of chemical reactor melt pumps:

◆ Stabilizing outlet pressure;

◆ Improving the products quality;

◆ Increasing the extrusion output;

◆ Reducing unit energy consumption;

◆ Prolonging the service time of extruder.

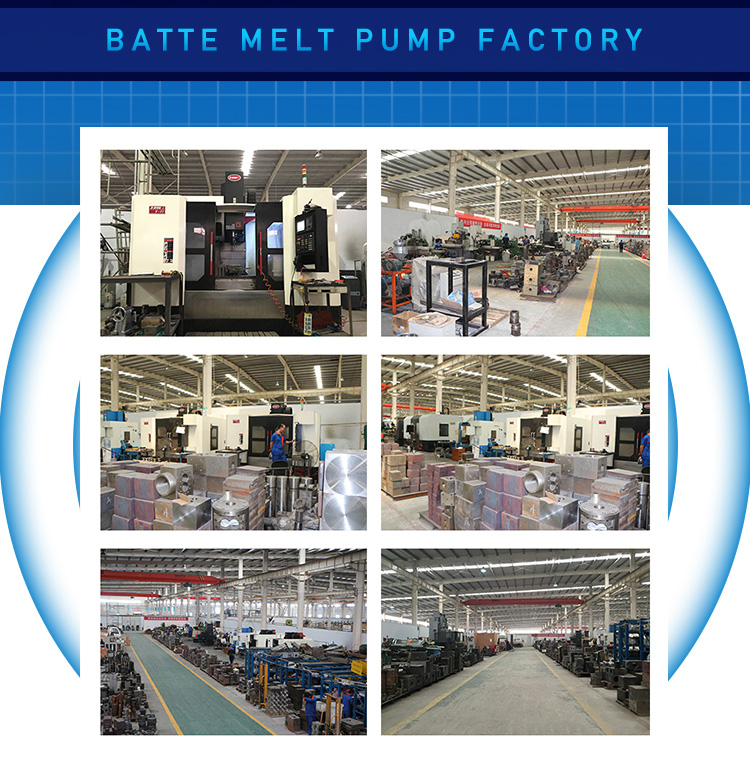

batte machinery zhengzhou CO., LTD:

Batte Melt Pump Zhengzhou Co., Ltd. is one of the manufacturers of melt pumps, gear pumps, metering pump and loss-in-weight feeders, volumetric feeders,screen changer in China. Batte has many experienced and outstanding plastic machinery talents, so it can continuously develop the new products by self-innovation or by introduction and absorbing new technology, meanwhile Batte also improves constantly the design of products and production technology service.Our pumps are widely used in plastic, resin, plate, sheet and rubber extrusion. For example, plastic extrusion machinery for PA, PP, PS, PE, PET, PC, ABS and so on is all using melt pumps to eliminate extruders' surge and screws' beat.

pre:ZB-D gear pumps for pipeline

next:ZB-R extrusion rubber pump